This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Environmental responsibility

We're driving sustainability, as manufacturer of the world's most energy-efficient hot-holding units

We are committed to achieving Net Zero Carbon by 2030, enhancing the sustainability of the entire business with innovative energy and carbon-saving solutions.

Our award-winning equipment and expertise lead the industry in sustainability, and we believe our business should too. We’re passionate about protecting the environment and reducing our energy consumption – in the same way we reduce the energy you use to make and serve hot food.

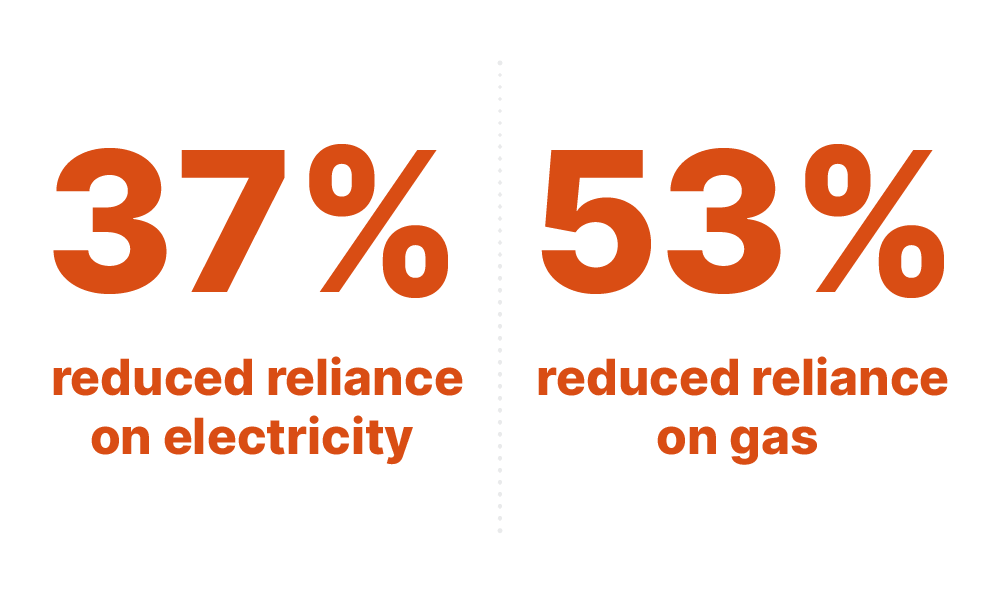

Reducing energy

We’ve removed 37% of our reliance on electricity, 53% of our reliance on gas and want to do more. The progress we’ve made so far has been achieved through many initiatives, including electrifying our vehicle fleet, installing smart LED lighting and air conditioning, and our insulated loading bay facility.

Removing plastics

We’ve limited the use of plastic across the business, and that includes how our units reach you. All UK deliveries utilise 100% reusable shipping materials and exports are shipped on wooden pallets with recyclable cardboard sleeves.

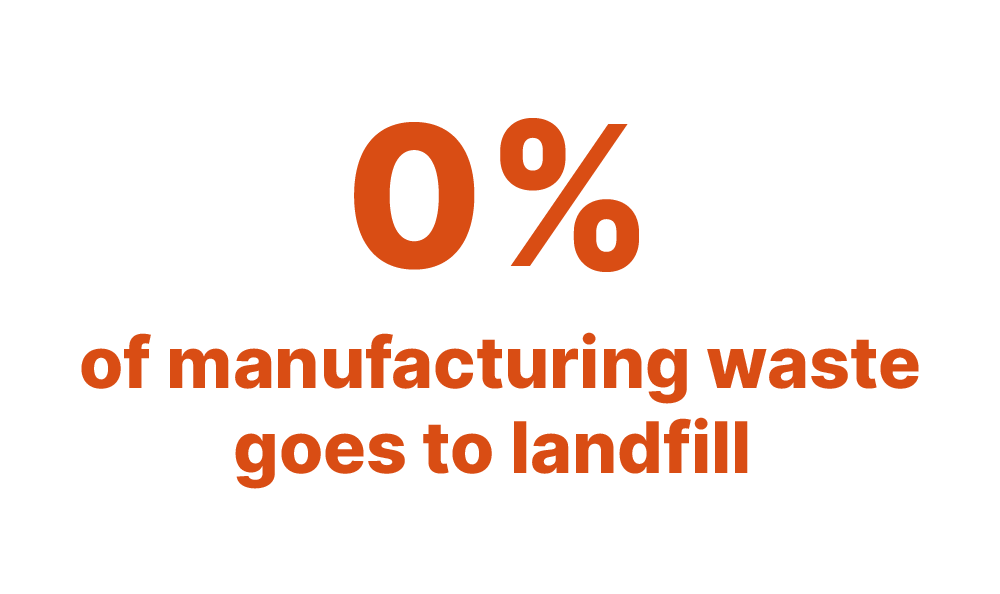

Wasting less

We help you sell more and waste less, and we’re all about wasting less. In fact, since July 2022, 0% of our manufacturing waste has gone to landfill. We actively encourage our team to reduce non-recyclable waste – we’ve even given every Partner (employee) their own reusable water bottle!

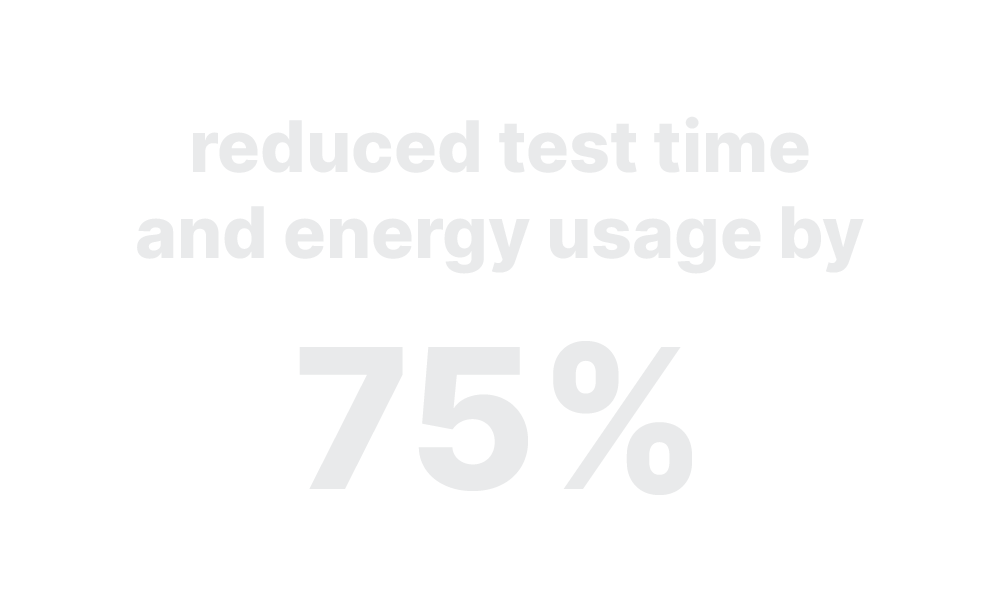

Refining processes

We are constantly looking to optimise our processes to deliver better efficiencies. For example, for our new testing process, we invented rapid in-line testing machinery and procedures – unique to our business – reducing our test time and energy usage by 75%.

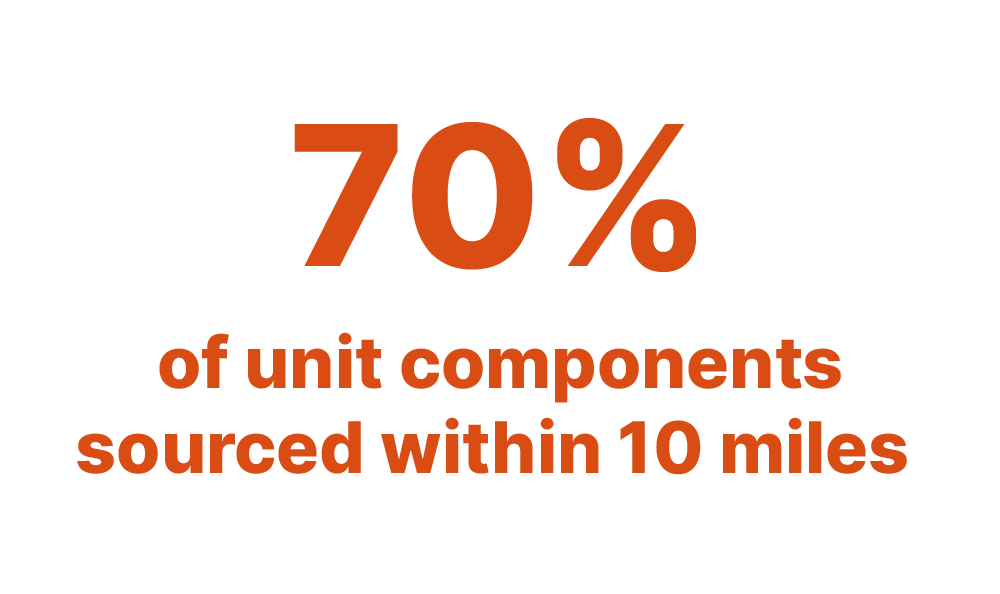

Sustainability in supply

Flexeserve prides itself on its reliable, international supply chain. However, 70% of our units' components are sourced from within just 10 miles of our Global HQ in the heart of Leicestershire. Across our supply chain, we seek to ensure we’re working with businesses that share our sustainable vision.

We’re part of the change

Flexeserve is fully engaged with the latest in industry thinking, as a manufacturer. Flexeserve is part of Warwick Manufacturing Group’s Net Zero Innovation Network Cohort, which helps to identify the next steps we need to take in our journey to being zero carbon.

![]()

Our products help you sell more, while wasting less ...

Innovative energy-saving features

Reduced thermal impact on store environment

Recyclable and compostable food packaging

Reduced food waste

Reduced single-use plastic packaging